Aerospace and Defence Testing

ACE has worked with numerous defence companies for climatic, dyno and vibration work. By stimulating real-world usage conditions in a controlled environment, we have allowed defence contractors to iteratively develop their systems and subsystems to confirm performance and mitigate issues. The outcome is better designs and more confidence in field performance.

Our engineers test equipment for complete systems, sub-systems and components used in development, production and research applications.

The five chambers at ACE enable aerospace and defence product development under some of the most extreme climate conditions found on earth. This can be accomplished on complete vehicles and/or their components.

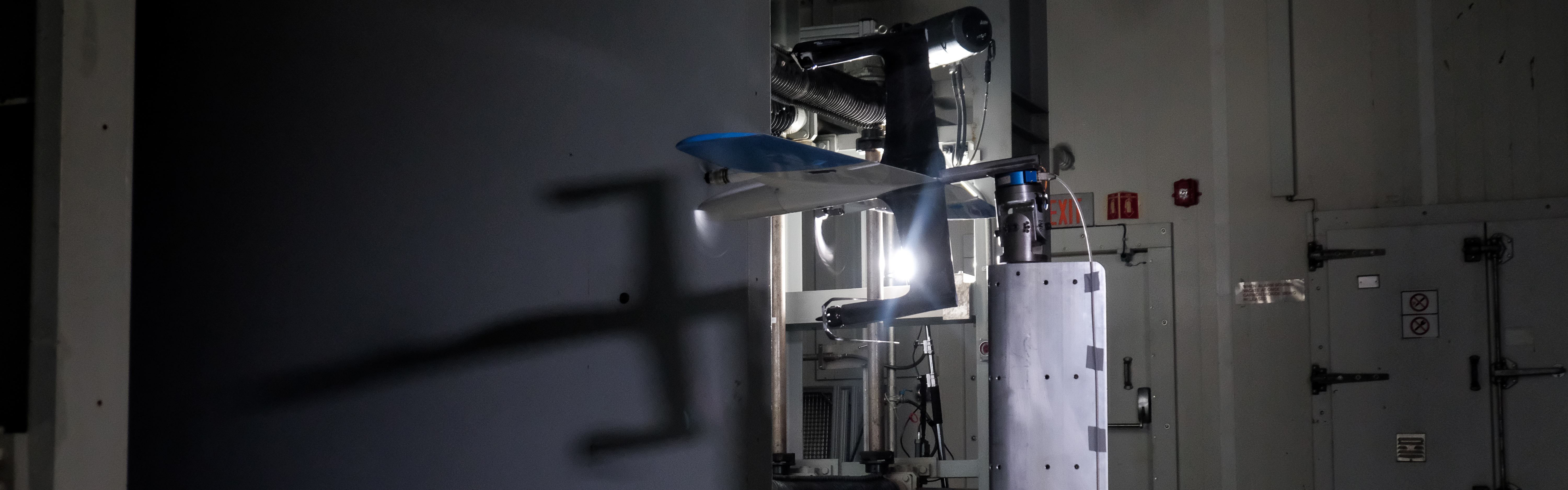

Flight Dynamics

ACE has several model support systems suitable for aerodynamic testing of scale models and remotely piloted aircraft systems/unmanned aerial vehicles, plus several load cells to meet unique force and moment measurement applications. Electronically scanned pressure transducers are also available to measure model surface pressures.

Flight Vehicle Performance

Remotely-piloted aircraft system (RPAS) vehicle duration and controls performance testing can be performed under weather extremes such as sub-zero temperatures and blowing snow, freezing rain, etc. using tethered flight in the climatic wind tunnel. Also, structural durability and life cycle testing can be performed involving vibrations resulting from inputs such as turbulence and landing using the multi-axis shaker table (MAST).

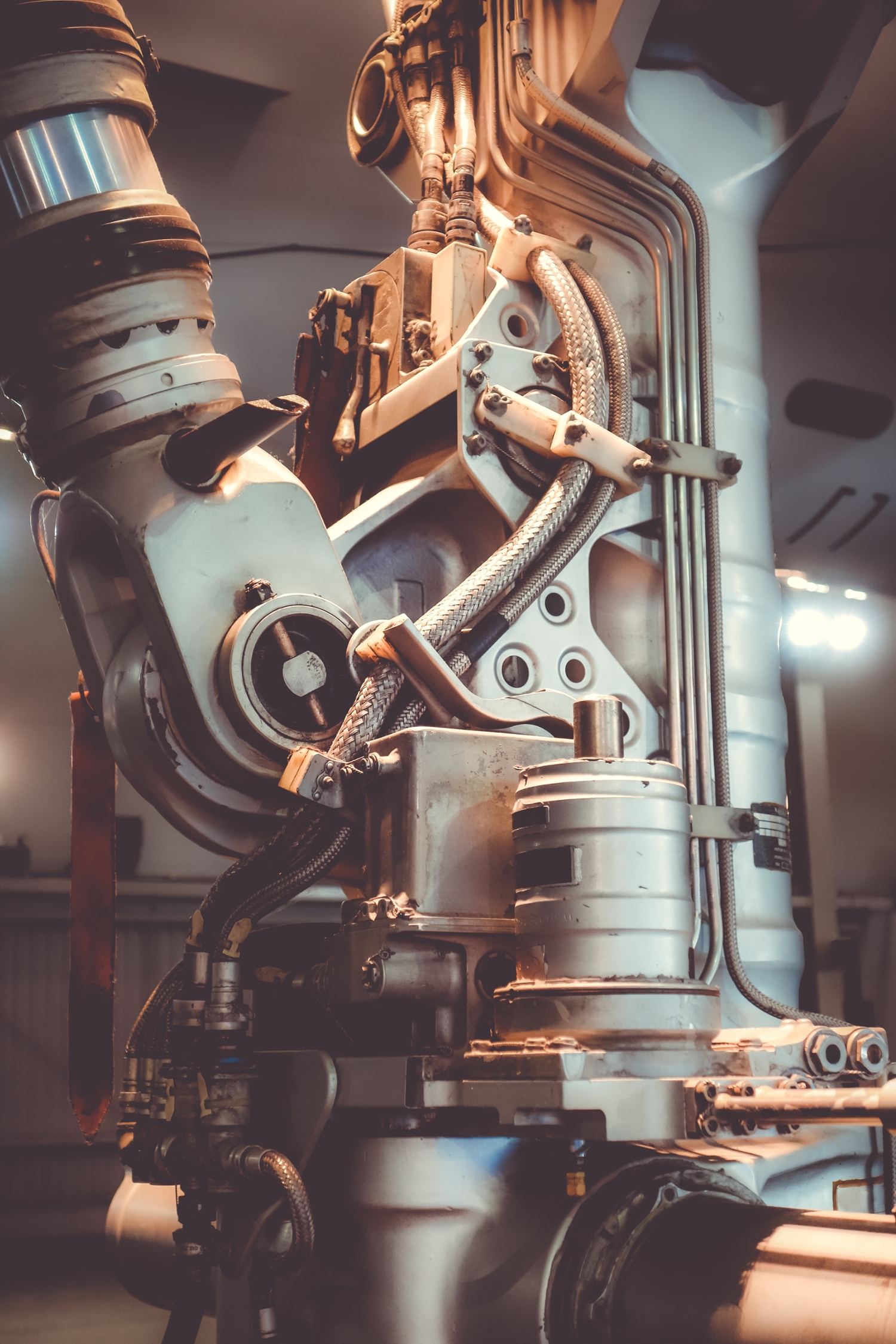

Military Ground Vehicle Performance

Performance of heavy vehicles and their components can be tested under severe environmental conditions, e.g. passenger compartment HVAC acoustics and thermal control. Typical tests include:

- Storage and operation under extreme temperatures.

- Functionality under ice accretion.

- Performance under snow intrusion.

- Operation under humidity extremes.

- Functionality under severe solar radiant heating.

- Effects of diurnal cycle extremes on vehicle and component safety, integrity and performance.

Military Standards-Compliant Testing

ACE is a Controlled Goods Program registered, providing high-security testing. Also, ACE staff are experienced in following military standard test protocols such as MIL-STD-810H, MIL-PRF-83812D and many others.

NATO DIANA Test Centre

The ACE Core Research Facility is part of NATO DIANA’s network of test centres. ACE will contribute by helping researchers and entrepreneurs develop dual-use technologies to keep NATO populations safe and secure. Being a NATO DIANA test centre and member of the Canadian Association of Defence and Security Industries (CADSI), ACE is Controlled Goods certified and has extensive experience working with well-defined policies and procedures to implement security while our clients are on site.

Being selected as one of NATO DIANA’s test centres enables ACE and Ontario Tech University to connect with an integrated group of military operators, the Alliance’s start-ups, scientific researchers, and technology companies on a greater scale. Through these connections, ACE and Ontario Tech University will continue to reflect the Alliance’s values of diversity, openness, and sustainability in their global mission of advancing deep technology with dual-use solutions.

Defence Department FAQ

-

Is ACE available for aerospace and defence testing?

Yes. ACE is one of the most advanced testing centres in the world. We have worked with many aerospace and defence companies in Canada and around the world. ACE is a one-stop-shop for aerodynamic, thermal management, climate and noise and vibration testing. Our engineers can collaborate with your team to develop the solution to your product development and/or testing needs.

-

Is ACE Controlled Goods Certified?

Yes, ACE is Controlled Goods Certified. We have long experience working with well-defined policies and procedures to implement security while you are on site. We can also work with you on any additional safety and security requirements you may have.

-

We have large test objects; is ACE capable of handling them?

ACE was designed and built to be a large industrial test facility. We have worked on many development and testing projects that involved aerospace and larger military vehicles. All of the size specifications of our chambers (and other information) is included on our Fact Sheet and on the Testing chambers tab of our website.

-

Our testing involves specific military specifications; is ACE able to meet these specs?

ACE staff have significant experience in following and implementing military standard test protocols such as MIL-STD-810H, MIL-PRF-83812D and many others.

-

We are interested in academic research support of autonomous technology; can ACE help facilitate this?

ACE is located at Ontario Tech University. ACE is also a lead in the Ontario Vehicle Innovation Network (OVIN). This provides us with a unique capability to bring together industry, academics and potential project funding for autonomous technology projects. Contact us to start the conversation about research collaboration.

-

Is there a defence component to climate physiology testing at ACE?

Yes. ACE was a key location in research from Defence Research and Development Canada Innovation for Defence Excellence and Security (DRDC IDEaS) related to climate physiology. Our chambers are capable of temperatures from -40C to +60C at any humidity level. We can work with you to develop custom climate physiology testing and/or training regimens that meet your needs.