Climatic Aerodynamic Wind Tunnel

The ACE Climatic Aerodynamic Wind Tunnel (CAWT) is one of the most sophisticated of its kind in the world. It is designed to provide a multitude of industries with world-class and independent testing capabilities to validate prototype products under a wide range of climatic conditions. Climatic simulation systems include solar capabilities, rain, freezing rain, light snow and blizzards - all with wind speeds capable of 300 km/h at temperatures ranging from -40˚C to +60˚C. The ACE CAWT is unique due to its seven to 14.5 m² variable nozzle, which enables testing of subjects ranging from very small to extremely large, in a wide variety of wind and climatic combinations.

Examples of tests conducted in the Climatic Aerodynamic Wind Tunnel include:

- aerodynamic testing

- heating, ventilation, and air conditioning (HVAC) testing in vehicles

- physiological/cognitive tests (human trials)

- product quality control

- snow mitigation (architectural)

- thermodynamic testing

- wind turbines

Key features

- Adjustable nozzle (7to 13m2) and long test section to accommodate a wide range of vehicle sizes and types, from small cars to Class 8 trucks and buses, with wind speeds in excess of 240 kph.

- Temperature from -40˚C to +60˚C and relative humidity (RH) from five per cent to 95 per cent.

- Low background noise level (64 dBA at 50 kph) for the detection of vehicle drive-away anomalies such as misfires, transmission hesitation, etc.

- Unique independently powered rolls chassis dynamometer in a turntable to enable crosswind testing.

- Solar simulation system up to 1,100 W/m2 intensity with sunrise-sunset simulation capabilities.

- Complete suite of ancillary systems for customer vehicle operation, including hydrogen and electric vehicle compatibility.

350 kW DC Fast Charger and Hot Road Soak Testing

ACE recently introduced the 350-kilowatt, 500-amp modular DC Fast Charger, which permits faster charging with the capability to operate in a temperature-controlled environment in three of its five chambers, the Climatic Aerodynamic Wind Tunnel, Large Climatic Chamber, and Small Climatic Chamber. As the future of the automotive industry progresses, ACE provides OEMs access to a world-class research facility that will actively assist in guiding this sector towards the development of electric vehicles.

Remote Testing

CAWT Fact Sheet

Garage bays

Featured with the Climatic Aerodynamic Wind Tunnel is three high-secure garage bays that are available for use throughout testing. Garage bays come equipped with a hoist and tools and requires badged access for the highest level of secuirty and privacy.

Specifications of the Climatic Aerodynamic Wind Tunnel

- Test section dimensions

- Wind speed and thermal performance

- Background noise level

- Chassis dynamometer specifications

- Solar simulation system specifications

- Rain & snow simulation systems

- Ancillary equipment

Test section dimensions:

|

Overall dimensions |

|

|

Useable length |

|

|

Vehicle entry clearance |

|

|

Adjustable nozzle |

|

|

Canopy for buses |

22 m2:

|

|

Turntable diameter |

11.7 metres |

|

Boundary layer removal |

|

|

Vehicle exhaust extraction system |

|

|

In-chamber fuelling |

|

|

In-chamber power |

|

Wind speed and thermal performance:

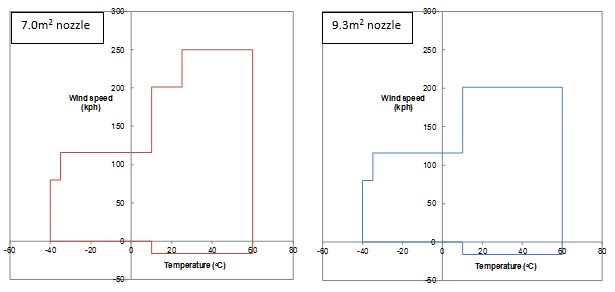

Full thermal control wind speed: 7 to 9.3 m2 nozzle settings.

Increased maximum wind speed: ambient conditions

|

Nozzle (m2) |

Wind speed (kph) |

Temperature (oC) |

|

7.0 |

280 |

25 |

|

9.3 |

250 |

25 |

|

13.0 |

225 |

25 |

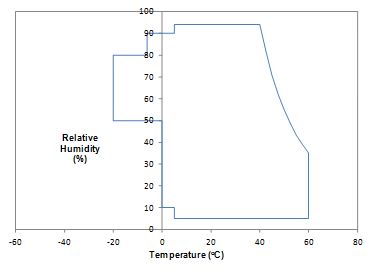

Humidity – temperature performance

Cooling system

- R507 primary loop with Dynalene HC-50 secondary loop.

- Total heat capacity: 500 kW at -40oC , 2100 kW at ambient.

Thermal performance

|

Parameter |

Set point change |

Rate |

Test condition |

|

Temperature |

<12°C |

0.8°C/minute |

70 to 105 kph; 32°C to 50°C |

|

<6°C |

0.6°C/minute |

<115 kph |

|

|

>6°C |

0.08°C/min |

<115 kph |

|

|

Humidity |

20% RH |

1% RH/minute |

38°C dry bulb |

Flow quality

|

Parameter |

Uniformity (σ) |

Stability |

|

Wind speed |

1% of set point |

±0.5 kph |

|

Flow angularity |

0.5° |

|

|

Temperature |

0.3°C |

±0.2°C at velocity > 48 kph |

|

Humidity |

0.5°C (dew point) |

±0.5°C (dew point) |

Boundary layer displacement thickness

- δ* less than 5 mm at 0.9 m ahead of the front chassis dynamometer roll set at 90 kph, 25oC air temperature

Background noise level: 9.3 m2 nozzle

|

Wind speed (kph) |

Out-of-flow sound pressure level (SPL) (dBA) |

|

50 |

64 |

|

100 |

81 |

|

140 |

90 |

|

250 |

107 |

Chassis dynamometer specifications:

|

Manufacturer and model |

Burke E. Porter (custom design) |

|

Vehicle types |

Passenger car, light and medium duty trucks, buses |

|

Axle configurations |

|

|

Roll width |

812 mm (four identical) |

|

Roll diameter |

1219 mm (four identical) |

|

Roll surface |

Tungsten carbide, aggressive finish (0.8µ) |

|

Clear space between rolls |

1,067 mm (identical front and rear) |

|

Wheelbase range |

1,600 to 5,842 mm |

|

Location of front fixed axle from nozzle exit plane (0o yaw) |

3,000 mm |

|

Location of rear fixed axle from nozzle exit plane (180o yaw) |

9,200 mm |

|

Normal maximum yaw angle range |

±30o |

|

Floor features |

|

|

Total inertial simulation range |

907 to 9,072 kg |

|

Maximum axle load |

5,000 kg |

|

Maximum vehicle weight |

9,072 kg |

|

Maximum speed |

250 kph |

|

Motor type |

AC (vector drive duty) |

|

Nominal maximum power |

187 kW per roll, motoring and absorbing; 92 to 250 kph |

|

Base speed |

92 kph |

|

Continuous tractive force rating |

7,301 N per roll ; 0 to 92 kph |

|

Tractive force overload |

150 per cent for 60 seconds; 0 to 92 kph |

|

Features |

|

|

Configuration |

Elevator and air bearings permit removal from test section. |

Solar simulation system specifications:

- Full diurnal function with azimuth and altitude.

- Full-spectrum capability with vertical and bi-axial movement.

|

Manufacturer |

KHS Steuernagel |

|

Target size |

|

|

Intensity range |

600 to 1,200 W/m2 |

|

Intensity incidence |

0 to 52.5o |

|

Spectrum |

ASTM Std E-892 |

|

Intensity quality |

|

|

Lamps |

|

Rain & snow simulation systems:

Rain simulation system

Frontal rain simulation system located at the nozzle exit.

- Up to 12 nozzles of various sizes as needed to provide adequate coverage of a given vehicle.

- Designed for 150 kph at 20°C but will operate as low as -5°C to perform freezing rain tests.

Snow simulation systems

There are two possible snow simulation configurations: frontal (blizzard) and overhead. In both cases, snow guns are used to create the snow.

Ancillary equipment:

|

Vehicle starting power |

200 amp 12 vDC and 24 vDC |

|

Pressure radiator fill |

System capable of charging from a pressurized vessel. |

|

Gas tank and differential cooling |

Cooling water system to provide cooling during high-load tests. |

|

Refrigerant charging system |

|

Frequently asked questions

-

What makes the ACE Climatic Aerodynamic Wind Tunnel unique?

ACE’s Climatic Aerodynamic Wind Tunnel is unique in the world and available to be rented by researchers, product developers and testing organizations. The wind tunnel can provide a temperature range of -40C to +60C under controlled humidity levels, wind up to 250 km/h, rain, snow, ice, freezing rain and fog. It also has a turntable that enable cross-wind testing, acoustic treatments for acoustic testing, world-class aerodynamic wind flow and is hydrogen capable.

The CAWT will also have a Moving Ground Plane or Rolling Road for aerodynamic testing. And, in another world-wide first, will enable dyno testing and rolling road testing in the same air flow. Please see the Rolling Road fact sheet here (link).

The CAWT has been the site of research and testing of a wide variety test objects and subjects from bicycles to buses, wing suit flyers to firefighters, solar panels and vertical axis wind turbines and Olympic skiers and skaters. And also some of the world’s best engineered cars and trucks.

-

How is time in the Wind Tunnel priced? What are the "extra" charges?

The CAWT is priced on an hourly basis. The hourly rate is dependent on wind speed, temperature and other required climatic conditions such as snow, ice or rain. If soak time is required to bring your test object to a pre-determined test temperature, soak time is allocated at lower price than testing time. All pricing is clearly displayed in a quote provided to you before you test.

ACE does not “nickel and dime” our clients. The hourly CAWT rate includes an engineer, a chamber operator, and a dedicated service bay during testing (a bay can be reserved for before and/or after testing for a small charge). ACE has conducted over 3,000 tests – we have highly qualified engineers and technicians to help you design your test plan and then execute the plan in an effective and efficient manner. ACE has the experienced team to deliver the solution to your testing needs.

-

We are concerned about Intellectual Property - does ACE have the required security to keep my IP safe?

Yes, ACE has many security procedures and protocols and is Controlled Goods-certified (for Canadian defence testing) so we are well-versed in working with our clients to maintain security and IP. We have many years of experience of working to implement security while you are on site. We can also collaborate with you on any additional safety and security requirements you may have.

-

We have large test objects; will they fit in the Wind Tunnel?

ACE was designed and built to be a Core Research Facility that was capable of handling large industrial-size test objects. All of the specifications for the CAWT are outlined below and are included on our fact sheet that you can download as a PDF here.

-

We are interested in academic research support for our project; can ACE help facilitate this?

ACE is a Core Research Facility of Ontario Tech University. This provides us with a unique capability to bring together industry, academics and potential project funding for projects. Contact us to start the conversation about research collaboration.