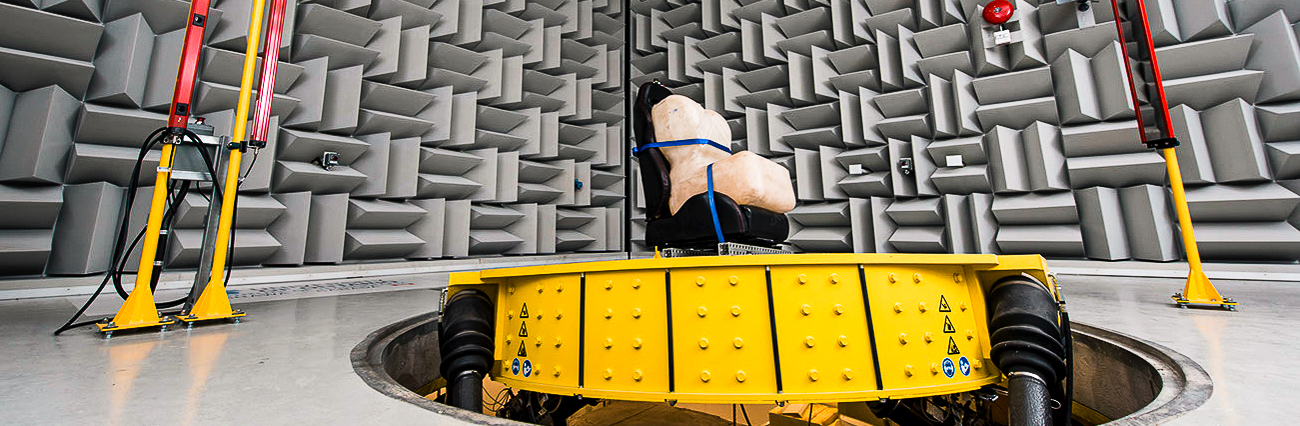

Hemi-Anechoic Chamber and Multi-Axis Shaker Table

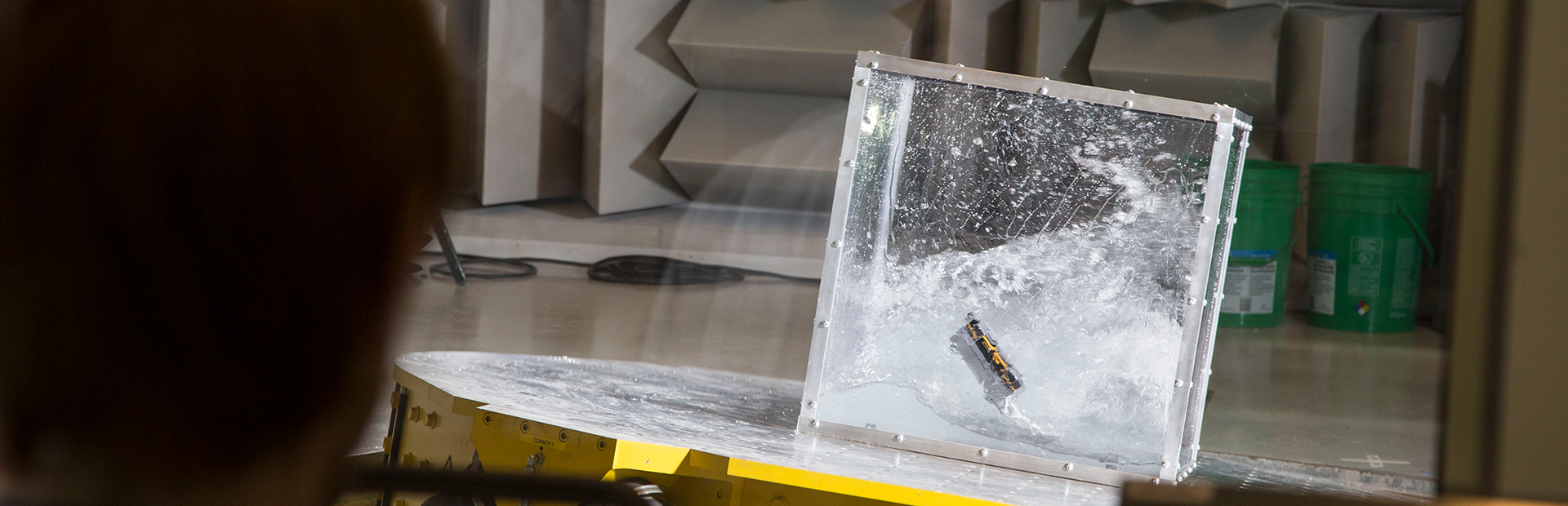

The ACE Hemi-Anechoic Chamber and Multi-Axis Shaker Table (MAST) is a unique and highly optimal space for product development and prototype validation of all kinds. It offers repeatable, high-frequency, six-degrees-of-freedom simulation of the vibrational environment of products and components. Being a hemi-anechoic chamber, this space is specially designed so that the walls absorb and break up sound waves, enabling microphones from our acoustic array to pick up the squeaking and rattling of test products.

The MAST is ideal for testing:

- Durability

- Noise, vibration, and harshness (NVH)

- Squeak and rattle

Sectors

Any sector that develops, tests, and brings new products or components to market will find immense value in the MAST. This space is also commonly used for Film and Media production. Sectors include:

- Automotive

- Defence

- Film and Media

Testing Examples:

- Air-turbulence and uneven-surface landing simulations

- Automotive components lifecycle/squeak and rattle

- Construction/architectural design and materials (earthquake simulations)

- Heating, ventilation and air conditioning (HVAC) subsystems lifecycle/squeak and rattle

- UAVs

Key Features

- 150 Hz cut-off frequency with exceptionally low background noise

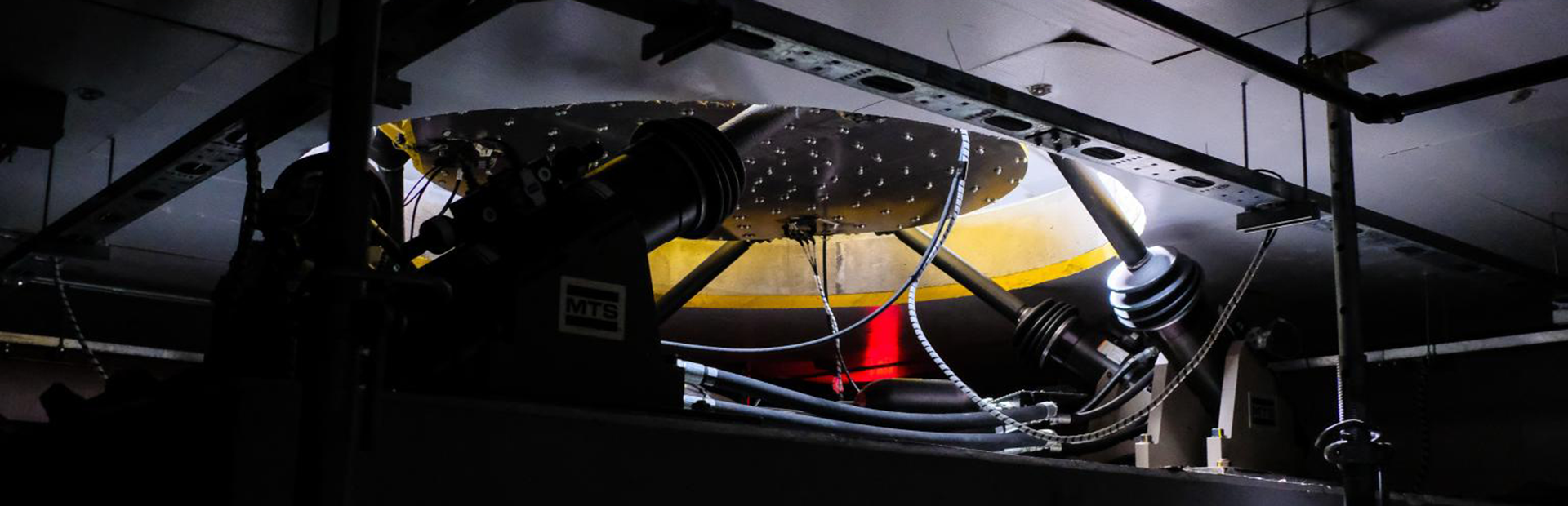

- Six-degrees-of-freedom (three translational; three rotational) inverted hexapod hydraulic shaker table

Specifications of the Hemi-Anechoic Chamber and Multi-Axis Shaker Table

| Overall Dimensions |

Inside Room Surface:

Clearance to Acoustic Treatment:

|

| Test-Object Entry Clearance |

|

| Chamber Acoustics |

|

| Pit Opening for Shaker Table |

|

| Safety | Laser-based light screen |

| Pure Acoustic Test Setup | Portable cover plates for pit |

| Manufacturer and Model | MTS MAST Table 353.20 |

| Control System | Flextest 100 with 793 System Software |

| Simulation System | MTS RPC Pro Software |

| Table Diameter | 2 metres |

| Test Object Max Payload Weight | 680 kg |

| Maximum Translation Displacements |

|

| Maximum Rotation Displacements |

|

| Maximum Velocities |

|

| Bare Table Response |

|

| Maximum Payload Response |

|

Media and Film

Acoustic Testing

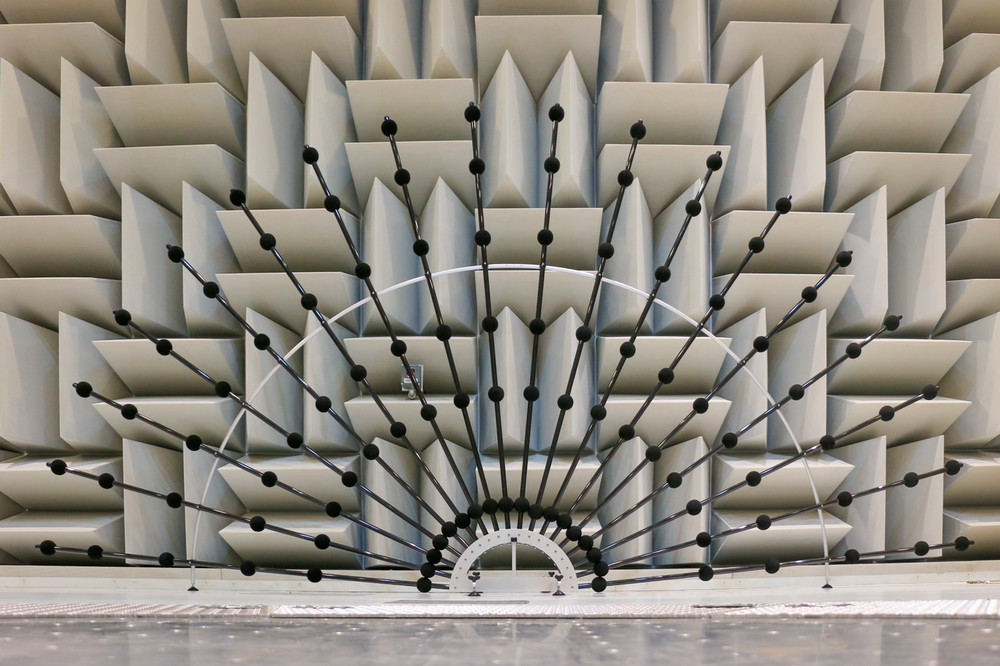

Acoustic Testing

Our Acoustic Array is ideal for Noise Source Identification. Featuring 108 microphones on 18 arms, it forms a half circle which utilizes the sound reflection off the ground plane of the chamber to effectively act as a full-circle array. Our array is portable and is most often utilized in the Hemi-Anechoic Chamber and the Climatic Aerodynamic Wind Tunnel.

Garage Bays

Three high-secure garage bays are available for use throughout testing. Garage bays come equipped with a hoist and tools and requires badged access for the highest level of security and privacy.

Frequently Asked Questions

-

Does ACE have the required security to keep my Intellectual Property safe?

ACE is Controlled Goods-certified for Canadian defence testing, so we are well-versed in working with our clients to maintain security and IP. We have many security procedures and protocols in place to implement your security, and we can collaborate with you on additional safety and security requirements you may have.

-

Can ACE help facilitate academic research support?

ACE is a Core Research Facility located at Ontario Tech University. This provides us with the unique capability to bring together industry, academics and potential for project funding. Contact us to start the conversation about research collaboration.