Testing Chambers

Climatic Wind Tunnel (CWT)

Climatic Wind Tunnel (CWT)

Our Aerodynamic Climatic Wind Tunnel can simulate multiple types of weather conditions a test object may experience throughout any season, such as extreme heat, snow, heavy wind and freezing rain. We can do this any day, at any time of the year and repeat the exact conditions as many times as required.

Large Climatic Chamber (LCC)

Large Climatic Chamber (LCC)

Featured with a long test section, the high feature chamber includes an input dynamometer coupled with a solar array. As well, it is complete with ancillary systems for customer vehicle operation, including hydrogen and electric vehicle compatibility. Large enough to fit test objects such as articulated buses, military equipment or locomotives.

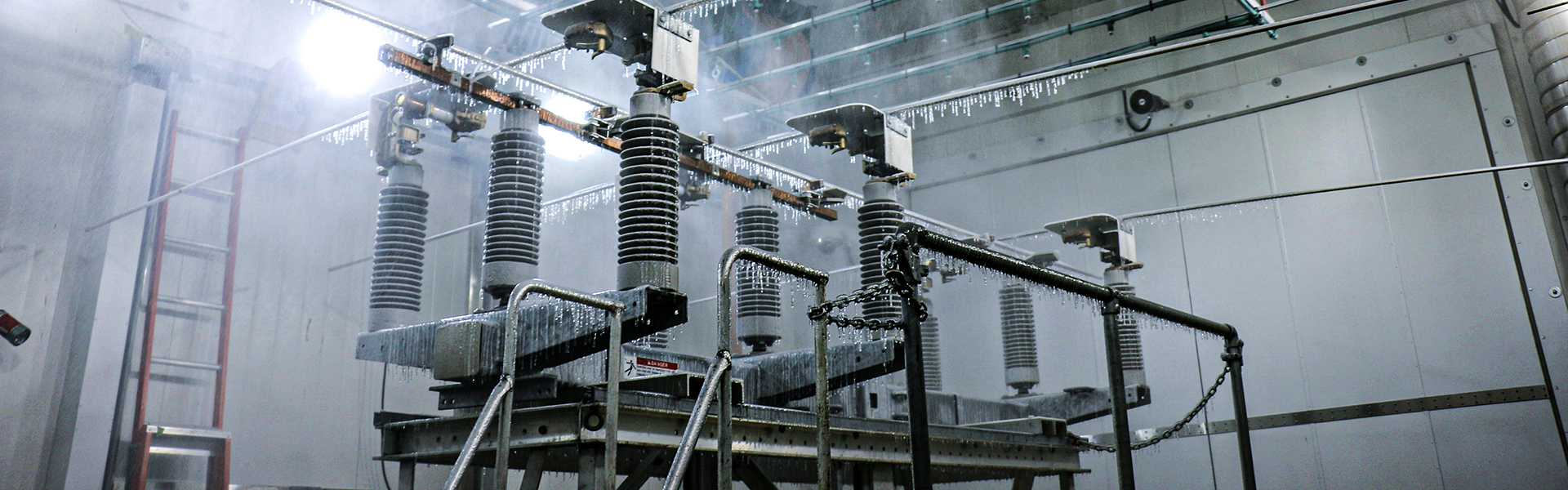

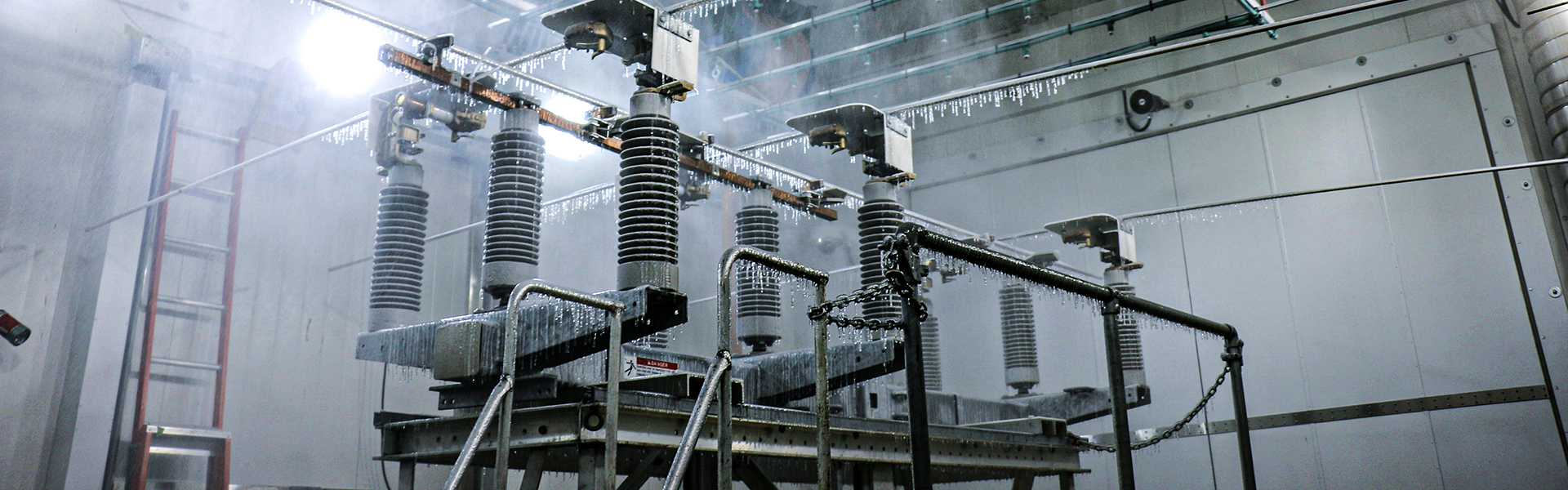

Small Climatic Chamber (SCC)

Small Climatic Chamber (SCC)

The small climate chamber is ideal for test factors such as repeatable temperature, humidity, or extreme conditions including freezing rain. Large enough to accommodate two vehicles, or an assortment of architectural prototypes. It is also possible to connect to the large climate chamber and climatic wind tunnel through an inter-chamber door creating a vast test section if required.

Climatic Four-Poster Shaker (4-Post)

Climatic Four-Poster Shaker (4-Post)

The four-poster shaker encompasses a traditional four-poster design situated in a fully climatic chamber. It tests products with four single-axis vertical actuators that move in an up-and-down motion. It can be programmed to simulate any condition such as a gravel road, high-velocity pot holes or jarring drop simulations.

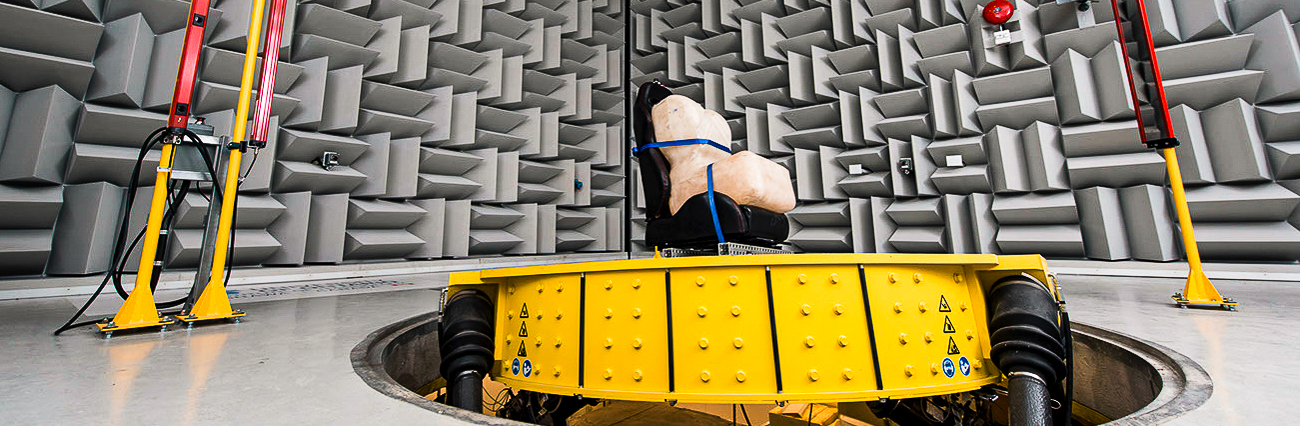

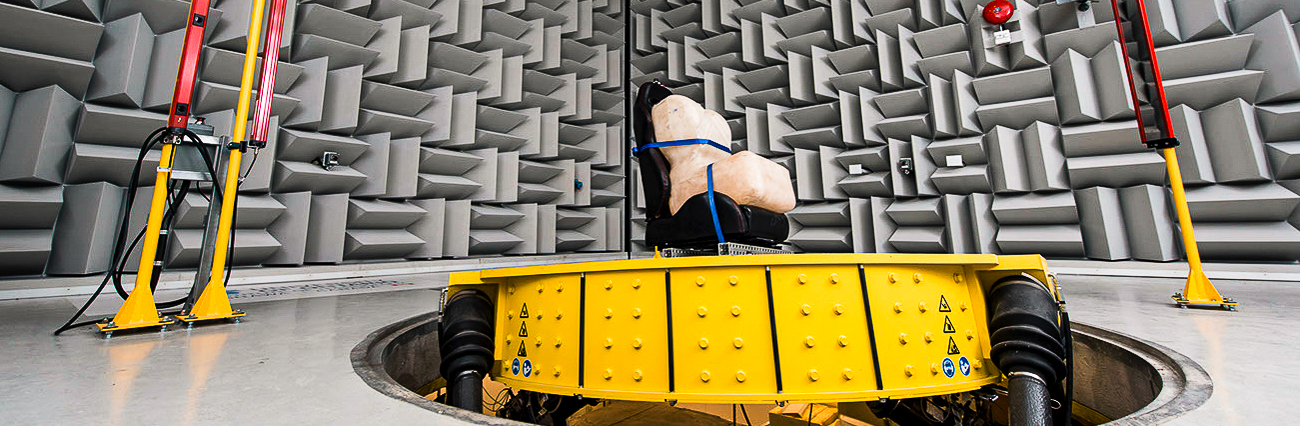

Hemi-Anechoic Chamber and Multi-Axis Shake Table (MAST)

Hemi-Anechoic Chamber and Multi-Axis Shake Table (MAST)

The multi-axis shaker table offers repeatable, high-frequency, six-degrees-of-freedom simulation of the vibrational environment of products and components. It is also located in an anechoic chamber, meaning the walls absorb/break up sound waves, enabling microphones to pick up the squeaking and rattling of test products.